Troubleshooting Melt Fracture

Single-screw extruders are the most common machines in plastics processing. Though basically simple in function, they are subject to many destabilizing factors that can result in out-of-spec product or a shutdown. When trouble strikes, you will need a strategy for identifying the causes quickly. An essential element of that strategy is the troubleshooting timeline. Here we’ll describe what it is and how it can be used to solve one common extrusion problem—melt fracture in tube and profile extrusion.

Start with sensors

Prerequisites to effective troubleshooting include good machinery instrumentation, current and historical process data, detailed feedstock data, complete maintenance records, and operators with a good understanding of the extrusion process.

Extrusion is a “black-box” process. We can’t see what goes on inside an extruder, so we depend on instruments. We need to be sure that all sensors are working and readouts are calibrated correctly.

These are the important process variables to monitor:

Melt pressure, typically about 100 times/sec.

Melt temperature every 1-10 sec with an immersion probe or every 1-10 millisec with an infrared sensor.

Temperature of the feed housing (if it’s water-cooled).

Barrel temperatures (one or two sensors per zone).

Die temperatures (one to 30 or more sensors, depending on die type).

Heater power in kw.

Cooling power, measured as fan rpm if air-cooled or water-temperature increase and flow rate if water-cooled.

Screw speed.

Motor load in amps.

Line speed.

Finished-product dimensions.

Other process variables may be monitored on upstream devices such as dryers, blenders, conveyors, and feeders—and on downstream devices like gear pumps, screen changers, calibrators, water troughs, laser gauges, pullers, and winders.

In order to solve extrusion problems, you have to understand the process. So operators new to extrusion should take classes covering material characteristics and machinery features such as instrumentation, controls, and screw and die design. Many extrusion operations, however, rely primarily on on-the-job training, though this is often the least effective and, in some respects, the most expensive method. Improper operation of an extruder by untrained personnel can result in costly damage or even injuries.

Troubleshooting timeline

To understand why a process isn’t behaving correctly, you have to compare current process conditions to previous conditions when the problem didn’t exist. Constructing a process timeline helps identify what changes in conditions upset the process.

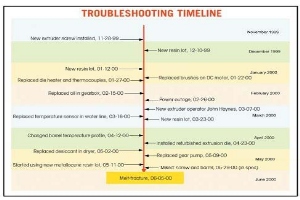

The timeline requires records from periods of process stability through the point when the process upset was noticed. You’ll need records of all process data—temperatures, pressures, and dimensions. Make sure to list all events that could have affected the process (see Fig. 1), like a power outage, change of screw, or a new resin lot. Some potentially important events are less obvious, such as construction in that area of the plant, changes in materials handling, maintenance activities on the plant’s water system, or the start of a new operator.

Note that not all events have an immediate effect. There can be a considerable incubation time before the effects of a change are noticeable, so it’s important not to jump to conclusions. It’s also important to start a timeline far enough back, even several months before the problem appeared.

Stopping melt fracture

A troubleshooting timeline helped a tubing processor to isolate the source of a processing problem. One extrusion line suddenly started making tubing with surface roughness caused by melt fracture. Melt fracture can take a variety of appearances—slip-stick (or “bamboo”), palm-tree, spiral, or random roughness (Fig. 2).

The timeline showed that the tube line ran well for nearly six months until the processor switched to a different resin. The timeline also showed that a thermocouple had been changed—another suspect. The thermocouple was checked for accuracy, and it turned out to be calibrated properly and was reading temperatures accurately. That left the resin as the most likely culprit. It was a metallocene-type polyolefin, which tends to be more susceptible to melt fracture because it maintains higher viscosities at higher shear rates—i.e., it is less shear-thinning.

In general, melt fracture involves stresses in the die and is often resin-related. It can be cured by either material or mechanical means. In this case, the processor could not change the material.

Melt fracture can be reduced or eliminated by streamlining the die flow channel, reducing shear stress in the land region, using a processing aid, adding die-land heaters, operating above the critical shear stress for melt fracture (known as “super extrusion”), or adding ultrasonic vibration—a little known but highly successful technique.

Streamlining the die’s flow channel is always a good idea to stop melt fracture, but it adds cost. For a high-volume product it makes sense to pay for a fully streamlined die, but that may not be worthwhile for a small-volume product.

Reducing shear stress in the land region can be done by increasing the die gap, reducing the extrusion rate, increasing die-land temperature, increasing melt temperature, or reducing melt viscosity. Viscosity can be reduced by using a process aid or lubricant. When 500 to 1000 ppm of fluoroelastomer is added to a polyolefin, it forms a coating on the die. This coating takes anywhere from five minutes to over an hour to form.

Other common solutions to melt fracture are to install a heater to raise die-land temperature to the point where the shear stress drops below the critical shear stress for melt fracture.

Residence time of melt in the die-land region is so short that temperatures there can be set relatively high. HDPE, for example, which processes at about 400 F, can pass through a die land at 575 F without degrading. Die-land heaters can be retrofitted on the outside of the land area of a tubing die.

A die-land heater can also reduce die-head pressure and give up to 20% higher extrusion throughputs while maintaining good product appearance and dimensional tolerances.

Super-extrusion is a technique in which shear stress in the die-land area is well above the critical shear rate for melt fracture. This is possible with HDPE and certain fluoropolymers (FEP and PFA types), which exhibit a second region of stable extrusion at higher shear than in the zone where melt fracture occurs (Fig. 3).

Ultrasonic vibration of the die with externally mounted transducers also causes shear thinning of plastics. Limited information is available on this technique, but it can reduce melt viscosity by orders of magnitude when the rate of deformation is high enough. The plastic melt layer at the die wall is most exposed to high-frequency deformation, resulting in a large drop in melt viscosity at the die wall. This reduces die-head pressure, die swell, melt fracture, and die-lip drool.

—Edited by Jan H. Schut

Chris Rauwendaal has worked in extrusion for nearly 30 years. He heads his own consulting firm in Los Altos Hills, Calif., which provides screw and die designs and process troubleshooting services.

By: Chris Rauwendaal , President from Rauwendaal Extrusion Engineering Inc.

From: Plastics Technology

Issue: October 2001